|

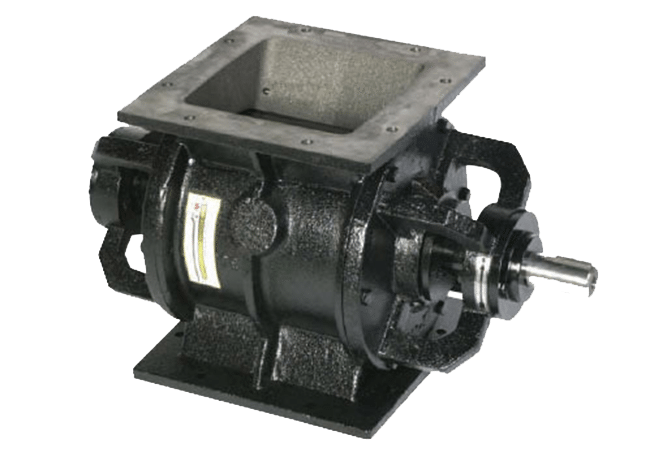

Rotary Airlock Valves

Troubleshoot Common Operational Problems

1. Material Jams

Material buildup can overload a motor, break a chain or  bend the rotor to the point that it breaks. This is more common in certain applications, such as conveying sugar or other sticky or powdery materials. Moist or humid conditions can cause those materials to stick inside the rotor. Also, know that some materials are more susceptible to jamming. These include stringy or fibrous materials, such as wood fibers, hard materials, like some plastic pellets and large, chunky materials. bend the rotor to the point that it breaks. This is more common in certain applications, such as conveying sugar or other sticky or powdery materials. Moist or humid conditions can cause those materials to stick inside the rotor. Also, know that some materials are more susceptible to jamming. These include stringy or fibrous materials, such as wood fibers, hard materials, like some plastic pellets and large, chunky materials.

What to Do

- Check the valve's rotation. Is it turning in the direction the manufacturer recommends? (View the rotation from the driven end). Correct valve rotation is especially important when utilizing beveled tips. With beveled tips, the wrong rotation can cause excessive drag and force between the rotor and housing. This can result in a failure of weld between the vane and rotor hub even to the point of the vanes separating from the rotor hub.

- Does the rotor turn smoothly without contacting the housing or headplates?

- Does the valve shudder? Shuddering can indicate material is jammed between a blade tip and the housing.

- Is your valve undersized? Material must fit comfortably in the rotor pocket.

- Has a foreign object entered the valve?

- Are changes to the material's properties affecting the flow?

- Is the material temperature higher than expected?

Remedies

- Bevel blade tips to ease flow between the blades

and housing or headplates. - Install flexible seal strips.

- If water vapor is reaching your your material and causing it to lump, vent moist air before it reaches the valve.

- Higher than expected material temperature may cause valve components to expand reducing valve clearances. Ideally, reduce material temperature. If not possible, valve clearances may need to be increased.

2. Excessive Air Leakage

No rotary airlock valve is 100% leak-proof. After all, valves are designed with clearances between the rotor and the housing and headplates.

Two types of air leakage in rotary airlock valves: 1. Clearance leakage: leakage through the blade-to-housing and blade-to-headplate clearances which usually decreases after the material enters the valve. 2. Displacement leakage: the amount of air entering each rotor pocket as the pocket passes the material outlet. This leakage increases with the valve's running speed and actual displacement.

Excessive air leakage may result in a drop in material throughput or in an increased air requirement in your conveying system. So how do you know if you have excessive air leakage? We can sum the clearance leakage and displacement leakage estimated by the valve manufacturer and go from there.

Ways to Minimize Air Leakage - Install flexible seal strips to reduce clearances

- Select a valve with more rotor blades

- Install a housing or headplate vent

- Install a vent adaptor at the material inlet

Avoid air leakage problems by discussing your clearance needs with a TEC Engineer. He or she will consider the material's characteristics, the operating temperature and application conditions (such as pressure differentials).

3. Noisy Operation

Some operating noise is common at startup. If your valve makes more noise than usual when running, or makes sounds you've never heard before, it's time for an inspection. - Ensure the rotor is running in the right direction and doesn't contact the housing or headplates. (See the importance of checking a valve's rotation in section 1 above.)

- Was the valve properly stored? If not, check for rust. Rust can reduce the clearances inside the valve.

- Build up inside the valve can cause noises. Material, especially hygroscopic material, can build up on the housing and headplates. Coating the valve interior with nickel or chrome often prevents material buildup. Or, try venting moist air before it reaches the valve.

- Bevel rotor blade tips to reduce drag.

- You could have a mechanical problem with the drive chain or drive shaft.

4. Low Material Throughput

Check for excessive air leakage. If that is not the problem and all of valve components check out, chances are your valve is the wrong size for your application.

We can work with you to choose the right size and configuration for a rotary airlock valve that is unique to your application. By considering your material's characteristics - bulk weight in lbs/cu ft, maximum particle size and the tendency to compact, aerate, absorb moisture, corrode or ignite - along with the device and conditions above and below the valve, you can avoid these common operating problems.

|