|

Industrial Magnetic Separation

Protect Your Process and Your Product

Foreign matter is the last thing you want in your product. Whether from something accidentally dropped into the product, like jewelry, or metallic pieces such as nuts, bolts, or metal shavings from damaged equipment, the consequences are serious.

- Foreign bodies can cause mechanical damage to process equipment.

- Under certain conditions, even one small, unwanted metal piece, loose in high speed rotating equipment, can lead to sparks and a dust explosion.

- Foreign bodies in food or pharmaceuticals can endanger consumers' health.

Fortunately, magnets have a long history of foreign body removal in process industries. The right magnetic metal separation equipment reduces downtime, eliminates contaminated product recalls and prolongs the life of your equipment.

Industrial Magnetics, Inc (IMI) offers magnetic industrial separators in sizes, strengths and designs to meet most applications. IMI also offers custom design and engineering for unique applications. TEC engineers can help you select the magnet that works best for your application.

Drawer/Grate Magnets

A common and efficient design for magnetic separation, drawer magnets consist of rows of round, magnetic tubes assembled into drawers, often with 2 layers. The magnetic tubes of each row are aligned on alternating centers from the row directly above or below it.

Product flow is forced to cascade in a zig-zag pattern from row to row over the magnetic tubes. Traveling through the housing, product comes in direct and repeated contact with a magnet which captures the tramp metal. The magnetic rods can be easily removed by pulling on them, like a drawer.

Plate/Chute Magnets

A plate magnet forces the product into a thin layer,  increasing the area of contact with the magnet. Ideal for angled chute metal separation applications, especially where product degradation is a concern, plate magnets are used for both above-the-flow applications, as well as below-the-flow applications. increasing the area of contact with the magnet. Ideal for angled chute metal separation applications, especially where product degradation is a concern, plate magnets are used for both above-the-flow applications, as well as below-the-flow applications.

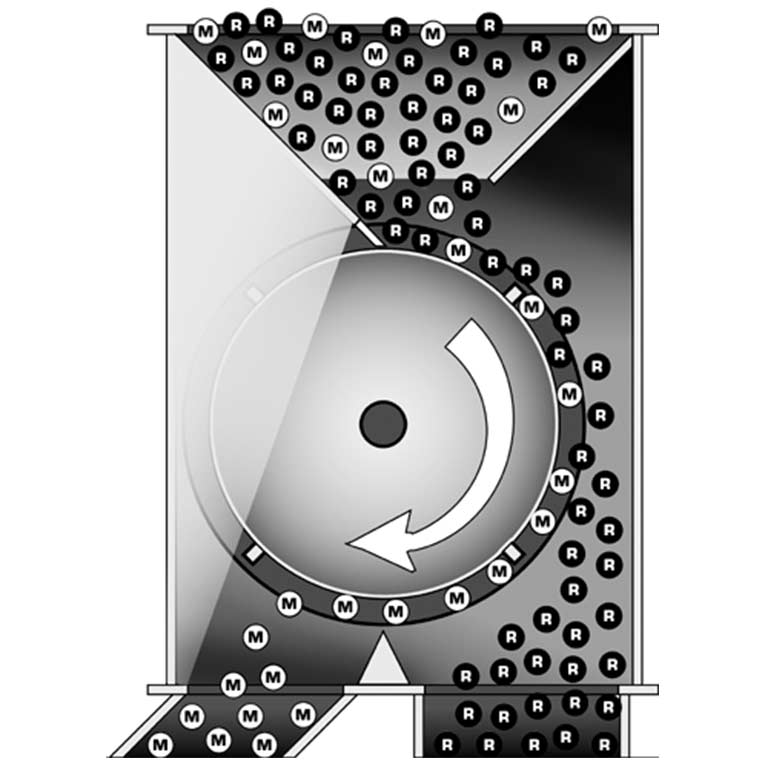

Drum/Rotary Magnets

Material enters the top of the magnetic drum separator and flows across the surface of the drum. The drum shell rotates around the stationary magnetic field, capturing any ferrous tramp metal. Unaffected by the magnet, non-ferrous product falls free from the drum into the cleaned material flow. The rotating drum carries the captured metal past the diverter, releasing it outside of the magnetic field. Rotating magnets are often used to overcome bridging of powder over the rods. They generally have a higher efficiency than static drawer magnets. Material enters the top of the magnetic drum separator and flows across the surface of the drum. The drum shell rotates around the stationary magnetic field, capturing any ferrous tramp metal. Unaffected by the magnet, non-ferrous product falls free from the drum into the cleaned material flow. The rotating drum carries the captured metal past the diverter, releasing it outside of the magnetic field. Rotating magnets are often used to overcome bridging of powder over the rods. They generally have a higher efficiency than static drawer magnets.

Bullet/Inline Magnets

Large, "bullet" shaped magnetic rods are designed for use in pneumatic line systems. Often placed ahead of processing equipment and bulk load out, bullet magnets help insure product purity and protect machinery from tramp metal damage. See a demonstration of IMI's bullet magnet in the video below.

|

| | Bullet® Magnet, Pneumatic Line metal separation from Industrial Magnetics, Inc. |

|

|

|

|

Two hikers snuck off the Appalachian Trail to a well known bakery. Forgoing

their keto diet, John bought 5 loaves of bread and Marc bought three.

Hours later, back on the trail, they sat down to eat their bread. Just then, a stranger came along, hungry and tired. He had no food but plenty of money. He asked to buy a portion of their bread. They agreed to divide all the bread

equally among the three of them.

After the meal, the stranger laid down eight coins of equal value for what he had eaten and went away. John, who had started with five loaves, retrieved five coins and left three coins for Marc. Marc disagreed. "We shared the bread equally, we should each get four coins".

Who, if either, is right?

|

|

QUOTE OF THE DAY

"Science can amuse and fascinate us all,

but it is engineering that changes the world."

-- Isaac Asimov

|

|

|