Explosion Protection A Collection of Papers, Videos, Case Histories and Other Instructional Material for the Bulk Material Handling Industry

Preventing Dust Explosions Requires Action

Combustible dust fires and explosions continue to occur at an alarming rate in the U.S. Each industrial facility faces its own set of challenges to control dust. Do you know the risks? To learn more, watch this video from the U.S. Chemical Safety Board.

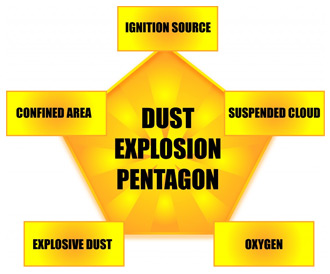

Know the Dust Explosion Pentagon

- Explosive Dust: The material must be combustible. Examples include sugar, plastics, coal, grains, flour, starch, and metals.

- Suspended Cloud: A dust cloud is created when accumulated dust spreads through the air. Settled dust can become airborne through everyday activities like sweeping, machinery exhaust and cleaning with compressed air. Shockwaves resulting from small, primary combustions are another cause of dust dispersment.

- Confined Area: The dust cloud must be in an enclosed structure, even one as large as a warehouse or factory, in order to achieve the pressure rise characteristic of a dust explosion. Without a confined area, flash fires remain a hazard but usually not explosions.

- Oxygen: Fires need oxygen to burn.

- Ignition Source: With all the above elements present, an ignition source is all it takes to activate a dust explosion. A multitude of ignition sources exist, ranging from smoldering or burning dust, hot surfaces, heat from mechanical impact and electrical discharges, even small sparks from a lit cigarette, static electricity, or metal parts scraping against each other